Sustainability is the only key to secure our future. Our Green Steel Strategy includes three core areas:

for the substitution of fossil energy sources

for climate-neutral internal and external logistics

for a reduced use of resources

By implementing comprehensive measures, we optimize resource efficiency for all business processes and infrastructure step-by-step. With our web application CO2 Balance, we can provide the complete product carbon footprint for each tonne of SWT Green Steel, which also includes transport to the agreed place of delivery.

Stahlwerk Thüringen is committed to the idea of recycling: since 1995, we have been using exclusively steel scrap as the basis for our steel, which is melted in the electric arc furnace. In this way, we reduce CO2 emissions by well over 50% compared to steelworks of the blast furnace route. As a result, we save more than a million tons of CO2 every year – that corresponds to the volume of 210 Cheops pyramids.

according to our EPD ISO 14025 and EN 15804+A1

according to our EPD ISO 14025 and EN 15804+A1

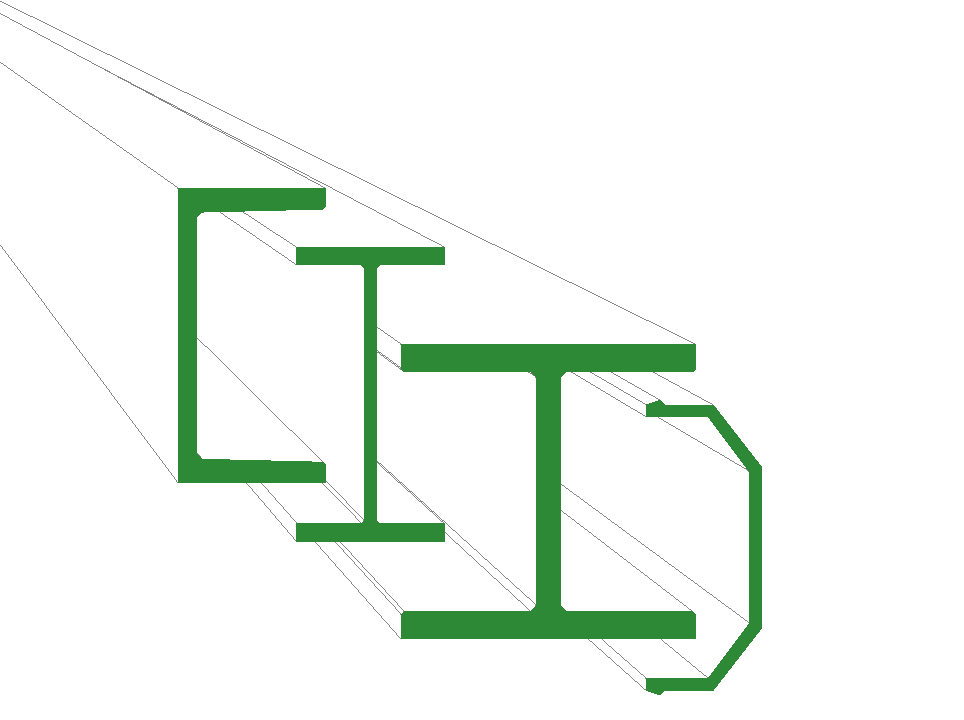

The demand for green steel is increasing: More and more customers are attaching importance to their carbon footprint. We support them with our production portfolio of steel sections, steel sleepers and special profiles.

We support European railways that, like us, pursue a consistently sustainable business policy in decarbonising their operations: Stahlwerk Thüringen supplies all infrastructure projects of Europe’s railways exclusively with SWT Stahlwerk Thüringen Green Steel®. These applications include:

We supply SWT Green Steel to all renewable energy construction projects worldwide, such as offshore wind farms.

immediately available for the entire product range

Head of Sales Coordination,

responsible for product management